- Home

- Spring Making Machine

- Potter Wire forming machine

Potter Wire forming machine

- Description

Description

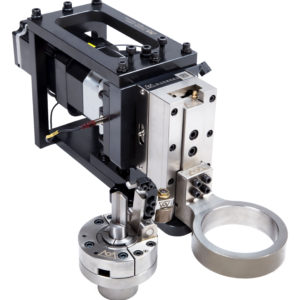

Model no. FV-210

Potter Spring former

Design:

The FV-210 based on the easy operation of the technical engineer, to develop the innovation mechanical structure and the servo control system. Anyone who is used to the computerized spring former can create the programs in the short term.

| Model No. | FV-210 |

| Wire dia. | 0.2~2.0mm |

| Max. slide movement value | 70 mm |

| Min. slide movement value | 0.01mm |

| Wire Feed Speed | 0~90M/min |

| Max. Feed value | 99999.99mm |

| Max. O.D. | 50mm |

| Max. Leg Length | 60mm |

| Max. Rotary Quill Angle | 360° |

| Min. Rotary Quill Angle | 0.1° |

| Power | AC 3PH 220V |

| Dimensions/Weight | 1720mm*1000mm*1650mm / 1050kgs |

| Motor of Rotary device | 1KW : Ø 0.2 ~ 2.0mm |

| Max. Rotary Angle | 0.1°~ +/- 360° |

| Industrial grade computer | Standard for 10 axis (Max. 16 axis) |

| Standard axis | 1 * Wire Feed |

| 1 * Quill Rotation | |

| 7 * Servo Slides | |

| 1 * Potter Rotary device |

● Servo Slides equipped with Servo full-functional Rotary device saves time for cam setup; and the simply

programming to set-up the spring.

● Identical wire diameter can be built the different products and suitable for small order without change

the tools.

● The innovative Rotary device is different from the traditional rotary wire disc and wire rotation

equipment. ODMAYTECH Patented Rotary device which is more lightweight to speed up the spring

production by 30% to 200%, It is especially suitable for the thin wire diameter. It can solves the instability

of fine wire in the wire rotation; and saves time of circular motion to move up the production speed.

● Integrated wire feeding mechanism Can be used for the lengthen Quill & line.

● Servo Slide saves time for the cam shafts setup.

● 360° Potter Rotary device can be improved the accuracy and stability of precise spring.

● Using the different tool for different functions. To install the Potter bender can be quickly bended; fitted

with coiling tool for coiling around spring body quickly; assemble the cutter tool for cutting.