- Home

- Spring Making Machine

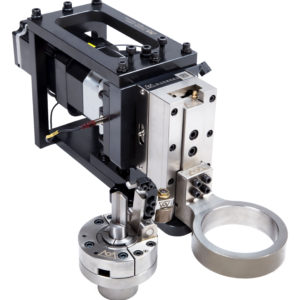

- FU-205 Potter cam spring forming machine

FU-205 Potter cam spring forming machine

- Description

Description

Description

Model No. FU-205

Design:

- ● Use the Rotary device to be substituted for the Rotary wire disc equipment.

- ● The Rotary wire disc is suitable for the medium/thick wire diameter, but it cannot be satisfied for accuracy

- and stability of the fine wire diameter.

- ● The Rotary wire disc is heavy and large which affects the production speed during rotation.

- ● Potter Rotary device runs flexibility and stability. It not only solves the instability of fine wire in the

- rotation, but also saves time of circular motion during running through the wire disc to improve accuracy

- and speed.

| Model No. | FU-205 |

| Wire Dia | 0.2~2.0mm |

| Max. slide movement | 60 mm |

| Min. slide movement | 0.01mm |

| Wire feed | 0~90M/min |

| Max. feed value | 99999.99mm |

| Max. O.D. | 50mm |

| Max. Leg Length | 60mm |

| Max. Rotary quill angel | 360° |

| Min. Rotary quill angel | 0.1° |

| Cam speed | 0~99rpm |

| Max. Cam angle value | 4000 |

| Min. Cam angle value | 1 |

| Power supply | AC 3PH 220V |

| Dimensions/Weight | 1650mm*900mm*1950mm / 825kgs |

| Motor of Rotary device | 400W: Dia 0.2 ~ 1.2mm |

| 1KW : Dia 0.4 ~ 2.0mm | |

| Max. Rotary Angle | 0.1°~ +/- 360° |

| Industrial grade computer | Standard for 5 axis (Max. 8 axis) |

| Standard axis | 1 * Wire Feed |

| 1 * Quill Rotation | |

| 1 * Cam shaft | |

| 1 * Slide | |

| 1 * Potter Rotary device |

Mechanical features:

- ● 360 ° Potter Rotary device can be improved the accuracy and stability of precise spring, and reducing the

- cost of the rotary wire mechanism as well

- ● Potter Rotary device increased machine capability by move up the production speed and reduce the time

- of the cam shaft setup.

- ● Identical wire diameter can be built the different products and suitable for small order without change

- the tools.

- ● Potter Rotary device up to 360° for replaces many complex tooling found on a standard spring machines.

- Equipped with servo Slide and Potter rotary tool to optimize operation and production speed