- Home

- Spring Making Machine

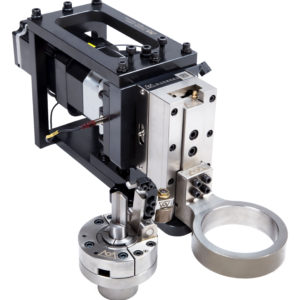

- FP-S1008 COMPUTERIZED SPRING FORMER

FP-S1008 COMPUTERIZED SPRING FORMER

- Description

Description

Model No. FP-S1008

Model Name: COMPUTERIZED SPRING FORMER

Introduction

The FP-S1008 computerized spring former specializes in producing various types of springs with 0.1-0.8 wire diameter. Patented Twin Axle Rotary Quill and Bending device allows you to operate rotary quill and bending unit individually, equipped with double transmission mechanism and the Parallel slide to perform the different spring of the same diameter in one machine. It offers the new technical solutions for increased productivity and cost optimization

Features

● Patented Twin Axle Rotary Quill and Bending device

The rotary quill and the bending unit could be running individually. It could be increase the service life of the quill & liner. It can solve the bending angle is too short if execute the bending action form the thicker side of the quill & liner to avoid the breakage quill.

● Integrated wire feeding mechanism

Make sure the accuracy and stability of the thin wire forming.

● Parallel slide

It can be simplify manufactured the different rotary directional and bending springs

Especially for double torsion springs, special-shaped, multi-bending springs

● Save the set up time and move up the productivity 20%-200%

USB access programming file for saving the set up time if re-production need

● Set up Identical wire forming without tool change

It can be produced by convenient programming of the different spring with the same wire diameter on one machine.

● Replacement wire rotation disc

The 360° rotary device replace the wire rotation disc, which it can be followed the trajectory of the spring forming to complete the processing quickly

● 360°Rotary device

360° Rotary device can be used the different tool for different functions. Assemble bender for bending quickly; assemble coiling tool for coiling around spring body quickly; assemble the cutter tool for cutting.

SPECIFICATION

| Mold No. | FP-S1008 |

| Wire dia. | 0.1~0.8mm |

| Slide stroke | 70 mm |

| Max. Feed value | 99999.99mm |

| Min. Feed value | 0.01mm |

| Max. Feed Speed | 0~90M/min |

| Max. O.D. | 50mm |

| Max. Leg Length | 50mm |

| Max. Rotary quill angel | 360° |

| Min. Rotary quill angel | 0.1° |

| Power source | AC 3PH 220V |

| Machine Dimensions | (W)1450mm*(D)750mm*(H)1650mm / 625kgs |

| Control device | Standard 10-axis |

| Standard axis | 1 * Wire Feed 1 * Rotary Quill 1 * 360° Rotary device 7 * Servo Slides |

| Rotary Angle | 0.1°~ +/- 360° |

| Motor of Rotary device | 400W : 0.1 ~ 0.8mm |

Optional accessories

| Single spinner | |

| Duble spinner | |

| Parallel slide | Plane translation left/right |

| Parallel slide(M1) | Plane translation left/right, forward/backward |

| Twin Axle Rotary Quill | Rotary quill and Rotary Bending device |

| 360° Rotary Bending device | |

| Customized quill & liner is available. | |