How Does A Cutter Work In Automatic Spring Coiling Making Machines While Manufacturing Springs?

How Does A Cutter Work In Automatic Spring Coiling Making Machines While Manufacturing Springs?

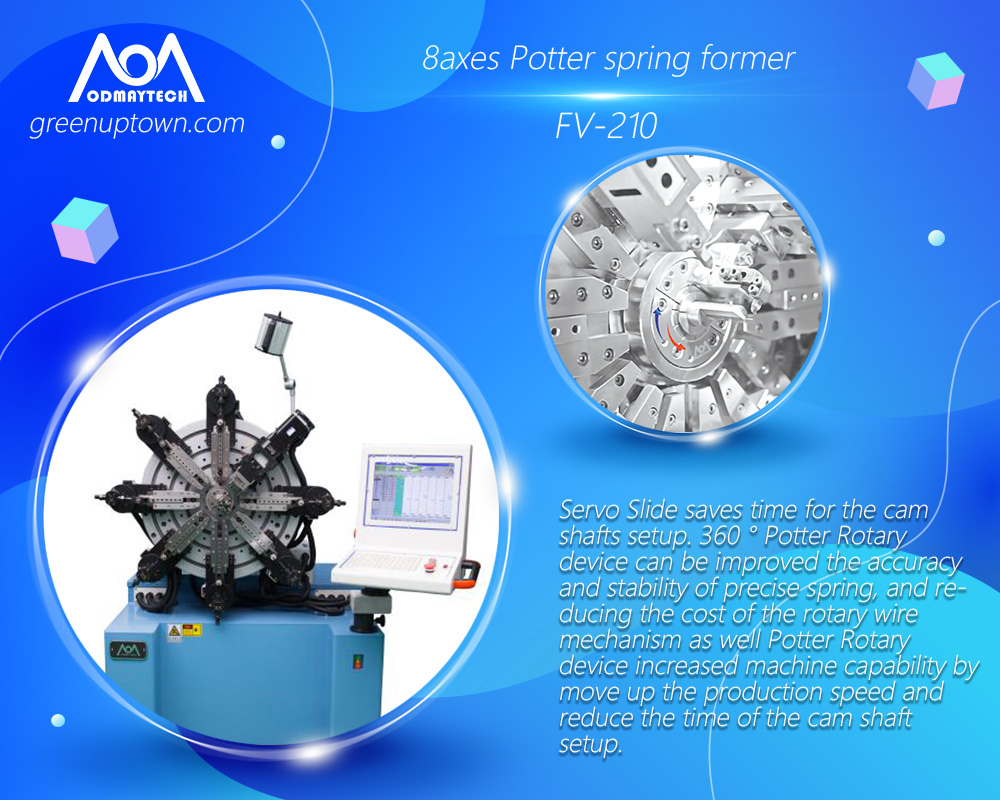

All the parts of a spring coiling machine have been deliberately put together to function as super machine. Not even one part can be said to be irrelevant to the entire working process of the machine. From the abor to the coiling points to other components, all the system parts are designed to synergize with one another for the best outputs.

This post will be discussing an important component of the spring coiling machine. You would be learning everything that is there to know as regarding the cutter of a spring making machine. In a sense, this should also give you a better idea of how such machines are to be used in the near future.

china spring making machine manufacturer (28)

Desired spring length

You can already begin to guess the functions of this machine component, even without really knowing much about spring forming machines. It is impossible for all springs to have the same length. The length of any spring is determined by what the client desires. So when different clients place their orders for different spring sizes, it is important that the spring manufacturers take all of that into account and does exactly so.

Cutters are spring forming machine components that work effectively in bringing the desired spring length into fruition. That means a manufacturer is not supposed to break his head on this at all. You do not have to second guess the output. With the cutter, the spring comes out exactly as the length should be. That is because every time the spring finishes its formation, the cutter is what will cut it out from the long spring material. This would have been a herculean task, but the cutters make it look so easy. It can be so perfect that you do not have anything to bother yourself about.

Different positions

There are a lot of things that obviously need to be considered when talking about how cutters work in spring forming machines. One of the many things you need to know is that the position of the cutter depends on the direction of the coiling. It can either be below the abor or it can be made to stay above it. Any of these directions can equally work fine for the cutter as it regard spring formation.

You will hardly ever find a spring forming machine that works outside this positioning. From what has been explained above, it should occur to you that that sort of arrangement may not be existing for now. Whether the position of the cutter, being above or beneath, will have anything to do with how effective the machine will work is a story for another day. But what we have learned here is that it can be seen in either of these positions that have been highlighted on this section.

The coiling point

For you to appreciate the actions of a cutter in a machine of this nature, you may want to also consider the coiling point. The coiling part of this machine is where the spring is forced into a coiling shape. Springs will have to go through this point before they are attended to by the cutter. So whatever happens here will equally have an effect on what will be received at the cutter.

Like we have rightly introduced at the beginning, the coiling point and the cutter of a spring coiling machine need to work collectively for high-quality output springs to be produced. If there is any issue with any one of these components, the resulting effect will be visibly noticed in the spring quality. Thus, for spring manufacturers to get the best out of these machines, it is best that you keep these two components in their best shape. Always maintain them as much as you can, and you can be sure of getting the best products.

An efficient machine

As much as we would like to restrict this discussion to what cutters do in a spring forming machine, we cannot do so without giving due consideration to how it influences the efficiency of the machine. A spring coiling machine cannot be said to be efficient when you have a faulty cutter. Whatever affects the activities of the cutter will indirectly affect the kind of output you will get.

The most successful manufacturers in this business are not just those who have all the skills and expertise. Success in this business equally boils down to how you maintain your working tools and equipment. For the sake of this discussion, we want to narrow things down to the cutter. It is imperative that you do everything you can to ensure that your machine cutter is in top gear. That alone would have a great impact on the ability of the machine.

Avoid a jammed cutter

Most spring formation processes are automated today. And if there is one thing you should fear when it comes to an automated process if for any of the parts to go bad. It will not only hamper productivity. It will equally have a devastating effect on the overall machine. I am 100% sure you do not want this to ever happen in the course of your operations. That is why we are crying here that you should keep an eye on your cutter and ensure it is always in good shape. The more your cutter is in good shape, the better for you and your business.

china spring making machine manufacturer (22)

Conclusion

Nothing is insignificant when it comes to the world of being productive with a spring forming machine. Your machine has got to be as steadfast as it can in order to keep the productivity level at a high one. That is just how things work, there are no two ways about it. The cutter of any spring coiling machine helps to cut the spring out from the parent material after it has been formed into the desired length. We also established that your cutter can be positioned below the abor or above it, depending on how the coiling has been designed to happen.

For more about automatic spring coiling making machines,you can pay a visit to CNC spring coiling machine, spring coiler manufacturer Greenuptown at https://www.greenuptown.com/spring-coiling-machine/ for more info.