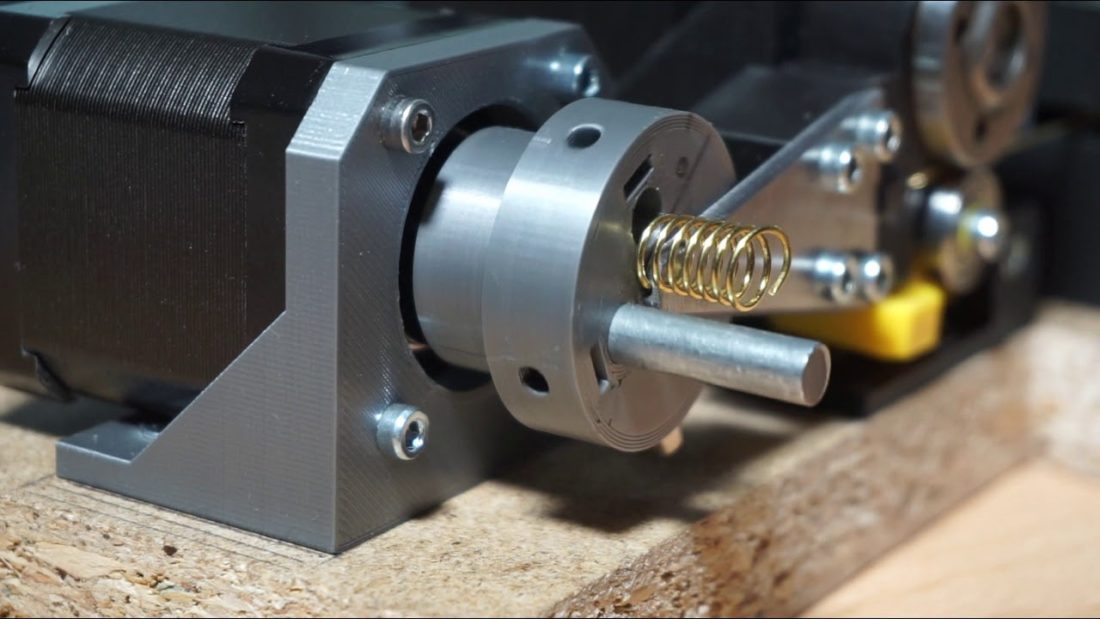

How to adjust the bending error of wire bending machine?

Cable bending machine is an automated gear capable of realizing high-efficiency and high-precision cable bending procedure. Althoughwe should pay attention to the correct operation and equipment conditions. Otherwise, the bending error will easily happen.

Possible ways for occurring bending malfunction in Machine:

Check the tool of the cable bending machine for damage. If the error caused by the application harm, then replace the tool to address the error.

When the tool doesn’t reveal any damage, assess there’s any issue with the standard of the cable.

When the above two problems are checked, still the error from the angle of the bending part, then it’ll be occurred due to the collapse of hydraulic system at the wire bending machine and the balancing mechanism doesn’t ensure that the pressure oil evenly enters the left and right cylinders. You need to adjust so.

Eventually, adjust the functioning mode of this wire bending machine to the state of”run adjustment”, then remove the mould in the machine, so that the slider can remain on the mechanical stop, then adjust the pressure gauge into the necessary one.

Concerning stress value, the particular technique is to compress the meter head of this cable bending machine by 3-4 mm, step on the pedal to let the machine boost, and if the bending machine process is boosting or the system is releasing, assess it. In the case of this hour hand offset of the dial index, the operation could be stopped if the given value is reached.

The above is the adjustment and handling measures for the bending mistake of the cable bendingmachine. In-order to avoid this situation, it is required to pay attention to the upkeep and proper functioning of the equipment regularly.