The automatic wire bending machine: Digital version vs the analogue version

The automatic wire bending machine: Digital version vs the analogue version

People tend to be sceptical anytime that the analogue spring coiling machine is mentioned with the digital spring coiling machine. The reason for this scepticism is usually down to the fact that most people do not know the importance of one over the other. One fact about both types of spring machines is that they are efficient in automatically helping companies to produce springs. However, there seem to be several differences between these two machines. Popular opinions about the machines seem to differ.

For example, some people are of the view that the analogue wire bending machines are much better than their digital counterparts. Alternatively, some people fancy digital spring machines over the analogue machines. With such varying opinions, it becomes difficult to settle for a particular machine. This post seeks to describe the differences between both machines.

china spring making machine manufacturer (17)

Before we fully get into the details of what the differences are between the analogue and the digital wire bending machines, it is essential to note certain important theories about wire bending machines. When it comes to the production of springs, these machines have proved more than effective.

The essential aim for this post is not to describe which machine is more superior than the other, rather the post aims to compare both machines and understand what makes them so different from each other. But regardless of these facts, any machine that you end up selecting will still give you a bang for your buck.

In the spring production industry, the use of the analogue and digital spring coiling machines is often seen as a significant breakthrough and they have completely transformed the way that the springs are produced.

With both machines, the wire bending process is fully automated leading to mass production of the coiled springs. This mass production process is often rapid and efficient. This means that choosing any one of the machines is not a bad business decision.

For most people that do not know that both machines differ, they can get familiar with these differences to understand which of the machines to use at different scenarios. These two machines come with different functionalities and features. These details often come with the manufacturer’s instructions.

The machines usually complement each other and there is no established theory that one is better. The strength of one machine can be the weakness of the other.

The differences between the automatic wire bending machine and the analogue wire bending machine.

With that mentioned, people who use the different spring machines will find it important to note the areas where the digital spring machine and the analogue spring machines are different. The following lists some of the differences between the two machines:

The operation mode of both machines

The analogue wire bending machines and the digital wire bending machines are much similar by the method in which these machines are operated. With this, we mean that the operation employed by these machines in the spring production process.

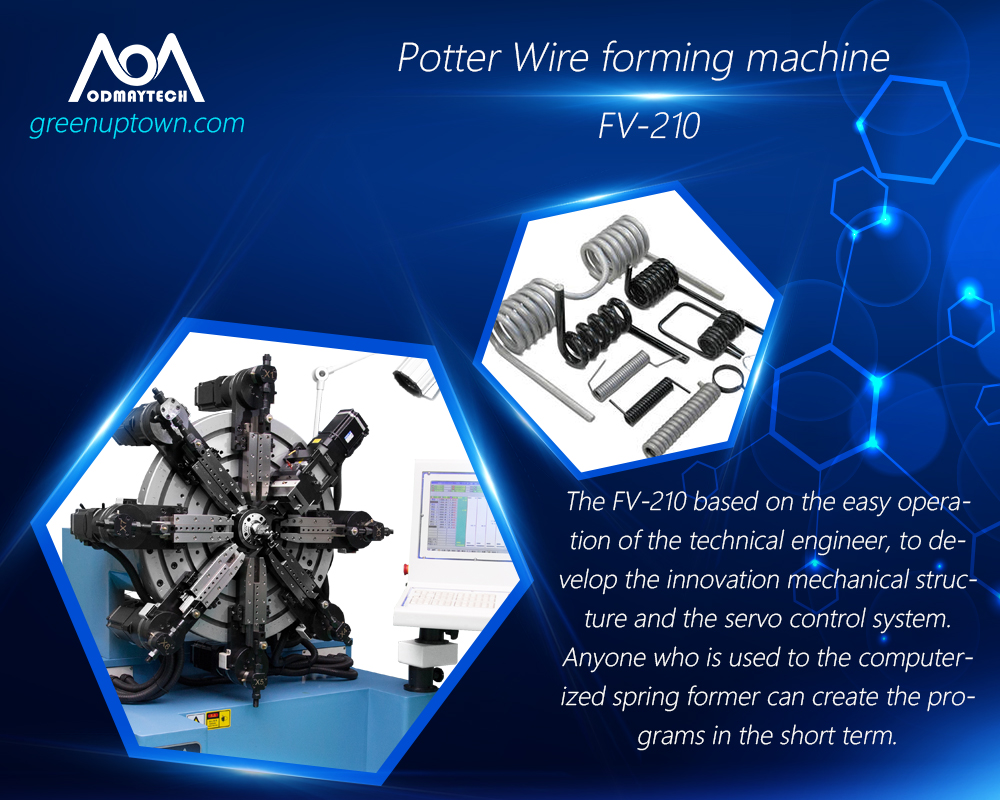

The digital wire bending machine is fully computerised. With this, your whole production line is controlled with the press of several buttons. This is a breakthrough from what the production process used to be. Before the development of the automatic wire bending machine, the spring production process was never this advanced. Previously, the spring production process was done with manual or analogue spring machines.

Technically, the manual processes involve a situation whereby all production stages are monitored closely to ensure that only minimal errors were made. The process was not initially computerised because the process was manually executed. It can be said that this process was semi-automated. Due to the inefficiencies of the semi-automated process, the automatic digital spring machines were finally introduced to help streamline the wire bending process.

With these types of wire bending machines, we have machines whose mode is fully automated in comparison with the analogue wire bending machines. The digital spring machine comes with a fully computerised working mechanism. This is has resulted in numerous benefits of the machine during the production process. For example, with the digital machine, you can easily choose shapes and types of springs with just a simple touch of the button.

The maintenance procedures of both machines

There is one benefit to using spring machines though, this is because they can be cheap to maintain. The analogue spring machine as compared to the digital version comes with cheaper maintenance. This analogue machine can cost in the region of between $10,000 and $15,000.

But for the digital spring machine, the price could be slightly more. However, form people who need one of these machines but seem to have a slightly limited budget, they can opt for the analogue wire bending machines. But it should be noted that with time, the maintenance for the analogue version will be more than that of the digital version. This is different from the digital spring machine that is cheaper to maintain.

For the digital spring machine, you do not need much maintenance since most of the production aspects are fully computerised. This means that the long-term costs of both machines vary.

Furthermore, one other thing that you need to consider in buying analogue machines is the number of operators needed to operate the machine during the process of production. The operators needed for the analogue machine have to undergo training. This will even increase the cost further. Alternatively, you need just a few operators to work the digital spring machines.

china spring making machine manufacturer (7)

The durability of both machines

It can be said that the analogue machines are quite costly in the long term in comparison to the digital machines. But it should be noted that the analogue versions have one significant benefit over the completely computerised counterparts. This is because they are very durable. The analogue versions have been carefully designed to have a longer lifespan and more rugged operation. The durability means that you get a bang for your buck.

With the above-mentioned facts, it can be summarised that both the analogue and digital wire bending machines differ in most areas. Thus, it is very important that you align your needs according to these features before you proceed to purchase one for your production facility.