How Is Digital Spring Making Machine Used?

How Is Digital Spring Making Machine Used?

Digital spring making machines have become the new wave of coiling machines in recent times. Their popularity is already growing way more than anyone can imagine. They have revolutionized and simplified the way these machines are operated. From their Stone Age operational procedures to their advanced computerized control systems, these digital monsters have been put through the necessary transitions.

A fraction of this post will be telling you how these machines are operated, while the other section will be telling us what else we need to know about them. Explained are some of the things you are supposed to learn about digital spring forming machines.

china spring making machine manufacturer (20)

The Historical Transitions

Spring coiling machines never started with the digital versions. It was the manually operated versions that were first used. As at that time, they were extremely large in size. Moving them from one point to another was a huge challenge. In addition to their manual way of operation, a lot of labor was needed to get it to work productively.

That was a huge source of concern for business owners who specialized on the production of springs. This development led technology enthusiast and researchers to concentrate on how they can improve the product and make it better for users. And with the subsequent versions to they came alive the size of the machines was drastically reduced. The more digital it became, the more compact it got. That was how these big machines transformed over the years to what they presently are.

Shortcomings of the manual version

The old version did not just fade away because they were big in size. Another reason they went into obscurity was because they had a lot of shortcomings. While some of those errors could be handled, some of them accounted for deformed springs. That made some businesses to run into losses. Naturally, those lapses began to signal the end of an era. It did not take that long before the digital spring forming machines began to access the market.

Business owners were a lot happier with it because the number of errors that were possible with the manual versions were reduced to the barest minimum. The digital spring coiling machines were a worthy improvement on their predecessors. With room for less errors, these machines made sure businesses achieved more within specific timeframes.

You had to do practically everything in the manual versions

The analogue spring coiling machines were boring and hard to use. It required people with deep knowledge of the system to operate them. From lining the springs on the machine to setting it the output that will be produced, you had to do virtually everything. For someone who is already familiar with the machine, this was easy. But for somebody who was just new to the machine, the reverse was the case.

This could only mean a lot of important resources were going to be affected. It will need more time to work maximally, since humans are the ones doing almost all the jobs.

The digital versions

A lot of things had to die with the analogue versions of spring making machines. It was an improvement that businesses had long hoped for. That single alteration was going to change the spring making industry forever. For one, the digital spring making machines did not require too much labor to function. In most instances, it only required one person to oversee the operations of the machine, and that is all. Most other activities were already managed by the computer. It also meant the cost of producing the springs was going to reduce since labor had been reduced.

Another thing that has also made the digital versions of this machine better than the analogue counterpart, is the fact that the competition among manufacturers is on the high side. Everyone is thinking of a better way to improve the product, and make it more productive.

Operational procedure

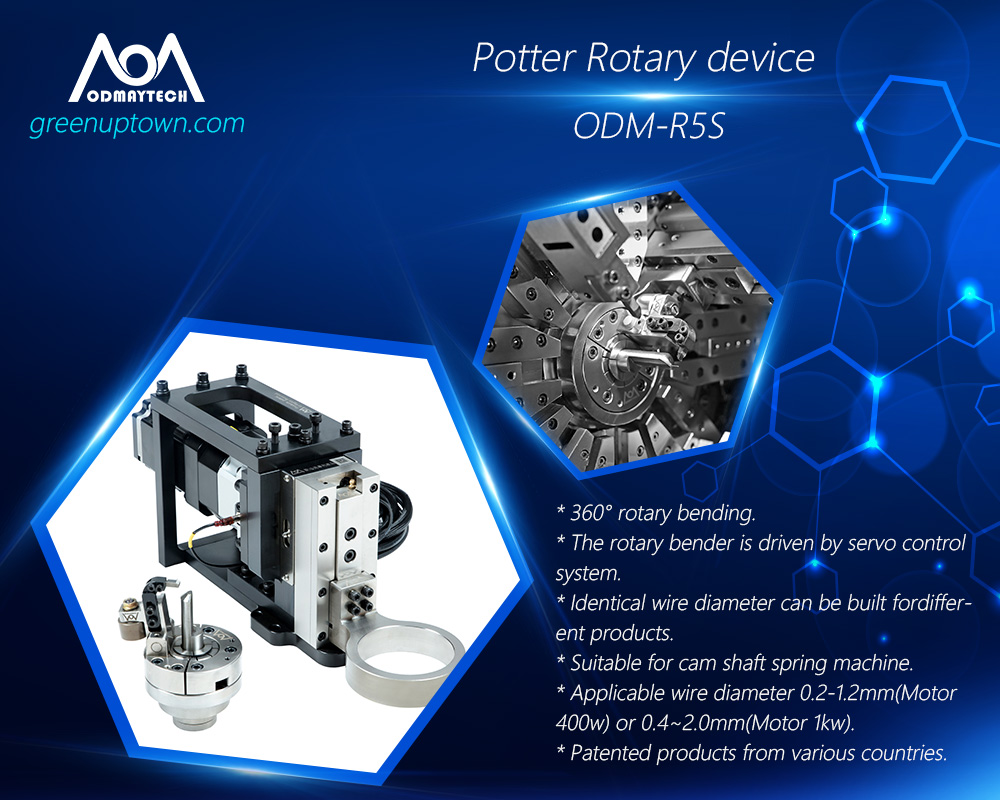

While everything was done with mere hands on the analogue versions of this machine, the operational procedure for the digital machine was similar to CNC machining equipment. It comprised a digital section and the physical responsible for churning out the springs. The digital components are responsible for supervising and controlling the way the machine operates. All it requires you to do is to feed your spring into the machine, while you manipulate the designs on the screen. You can set every other thing that concerns the way the spring would be produced. That way, there will not be too much room for you to make any errors.

Design flexibilities

The digital spring coiling machines was readily accepted by spring manufacturers because it was a lot more flexible in the area of designs. The design options of the analogue machines were heavily limited. You could only do certain designs. That is you can only design what the machine has been designed to work with. On the contrary, digital spring formers came with more options that will allow creativity.

As long as the designs can be arranged and verified on the system, they can be produced on the machine. Most of the designs and accurate parameter springs you see today were only made possible due to digital spring coiling machines. Otherwise, the use of the old machines would have created some sort of barrier for the spring industry, and that was the last thing they wished for.

china spring making machine manufacturer (19)

Conclusion

For us to appreciate how digital spring machines are used, one needs to discuss some other parts of the machine. Thankfully, we have done that in the course of the post. We also pointed out a couple of distinguishing factors between the digital spring formers and their analogue counterparts. The analogue versions blazed the trail for the digital types to come out. It was also emphasized that the digital machines seem to be more productive for obvious reasons. And that their modus operandi were less dependent on labor, resulting to lower costs of production. The digital spring making machines are a beauty to behold in this regard.

For more about digital spring making machines,you can pay a visit to china spring making machine manufacturer Greenuptown at https://www.greenuptown.com for more info.