How Does A Small Spring Coiling Making Machine Works?

Spring coiling machines have been dubbed as being among the most advanced machines in the world. This monster of a machine works in a magnificent way. Even as all the different spring coiling machine brands differ in terms of the method of manufacture, they have almost one principle of operation.

But no matter how complex these systems are, they were still built by human beings. A spring coiling machine works in a specific way, and that is what you have come here to learn. Therefore, this article will be discussing the mode of operation, as well as the accessories that work with this unique machine.

china spring making machine manufacturer (30)

How they function

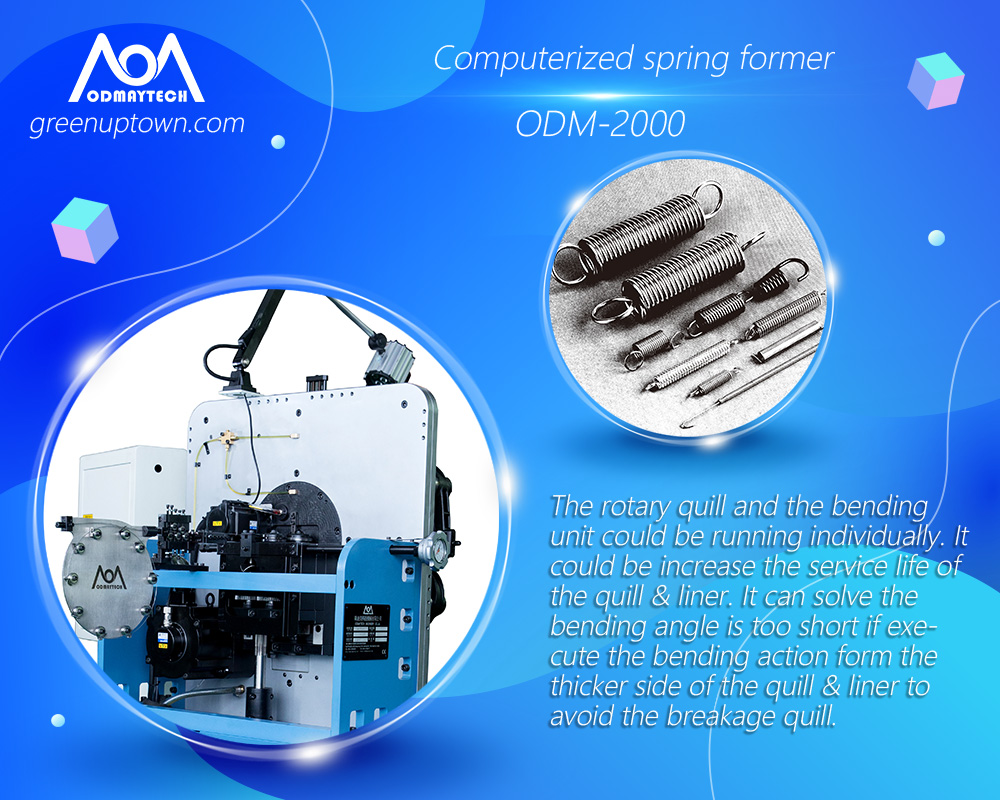

A spring making machine does not need a rocket science understanding to know how it functions. It is very simple to figure out when you see it. The steel alloy or any other material will be passed along certain parts of the machine. There is a component of the machine known as a coiling point. This is what forces the wire into the about to be formed spring looking shape. While this is happening, all the other parameters such as spring index, spring shape and diameter will be sorted out via the settings you must have done on the system before kick-starting the production.

The overall feature of the spring you get from the machine will depend on what you have chosen as your set parameters.

To help you understand deeply how these items work, it will be appropriate for us to take a glimpse into the various parts of a spring forming machine.

Feed rollers

These components rank among the most notable features you can find on several spring making machines. Just as their names imply, they are known to move in circular motion when they are in operation. So as they are rotating, they normally bring wires from the machine to where the wire guides are located. These feed rollers are mostly in 3 categories. The different groove sizes normally correspond to the groove within the wire groove.

Wire guides

These components are very important because of their flat shapes. They are meant to comprise groove sizes that will match with whatever size is on the feed rollers. The size of the groove may not be exactly the same with the size of the wire for it to be useful. However, the size cannot exceed a specific range, otherwise it will be useless. The wire will need to go through the wire guide before making contact with the block guide, coiling point, or the arbor.

Block guide

The moment the wire comes out of the wire guide, it makes contact with this point. The block guide is what will help guide the wire until it arrives at the coiling point. The groove that is set beneath the block guide ought to be the right size for it to fit with the diameter of the wire you are passing to it. The block guide is all about making sure the wire always stays on track.

Arbor

As the wire is going through the block guide groove, it also goes round the arbor. In one point coilers, the arbor is the third spot the wire touching during coiling. Spring physics states that there should be a minimum of three points for proper coiling to take place. For other two point coilers, it may not be necessary to have an arbor as part of the machine.

Pitch tool

There is going to be an up and down motion when the spring making machine is in its working process. As the wire is moving across the not so straight surface, the job of the pitch tool is to help keep the spring pitch in place. This component is very similar to the arbor in that it is designed to match every job. The pitch tool that will work for one project may not be exactly what is needed for another project.

Coiling point

Like it has been stated earlier, this component is what helps to force the wire into its coiled shape. It does so by altering the wire of the trajectory. The deflection angle of the wire will depend on the parameters that you have set. One way to distinguish between the numerous spring coilers is by looking at the number of coiling points present. The more the number of coiling points, the more productive you would expect that machine to be.

Cutter

The cutter can be likened to the last man standing. As the spring approaches the needed length, the cutter will be called into action to cut it off from the wire. At that point, a separate spring will be produced. The position of the cutter is usually not static. It can change. The position depends on whether the position of the cutter is below or above the arbor.

The above components are all basic components you can find in spring making machines. And that is not where it ends. You can use yours with other additional accessories. Some of those extra components include wire straightener, spring grinder, stress relief oven, power wire payoff, and some more components.

You ask what the need for these extra components is. The answer is simple – the more components you have as part of the working system, the higher the quality of the spring that will be manufactured.

china spring making machine manufacturer (29)

Conclusion

A spring making machine has a well-coordinated manner of working. They have been brilliantly designed to suit different design requirements. You do not need to have a special design model before you can adopt it. So long as it has to do with spring manufacture, you can count on these machines. A lot has been said on this post regarding how the wire material is passed along the surface of the machine to various points where it can be forced into the shape of a coil. You can discover secrets of how to optimize the productivity of your spring coiling machine when you have knowledge about the various components.

For more about small spring coiling machine,you can pay a visit to spring making machine manufacturer greenuptown at https://www.greenuptown.com